The Paper and Board Industry Advisory Committee (PABIAC) has set ambitious human factors targets in its 2023-2027 strategy. While many in the industry are familiar with engineering and procedural approaches to safety, human factors represents a paradigm shift—one that considers how people actually interact with equipment, procedures, and each other in real-world conditions.

This three-part blog series will guide you through meeting PABIAC’s human factors objectives while delivering tangible benefits beyond compliance. In this first instalment, we’ll explore what human factors really means, the current PABIAC requirements, and why traditional approaches alone aren’t enough.

What is Human Factors?

Human factors (sometimes called ergonomics) is the scientific discipline concerned with understanding interactions among humans and other elements of a system. It’s about designing for human capabilities and limitations rather than expecting people to adapt to poorly designed systems.

In practical terms, human factors means:

- Recognising that people are not machines—they get tired, distracted, and make mistakes

- Understanding how the workplace environment impacts performance

- Designing tasks, equipment, and systems that work with human psychology rather than against it

- Creating layers of protection that anticipate and mitigate the consequences of human error

Human factors isn’t new – aviation, nuclear power, and defence have long incorporated these principles. The process industries, including oil and gas, have made significant strides in the past decade, while other sectors are just beginning their journey. For the paper and board industry this is quite new, with PABIAC now accelerating this transformation.

Understanding PABIAC’s Human Factors Requirements

PABIAC’s strategy sets clear expectations. By December 2024, all sites must identify gaps in people’s knowledge and understanding of human factors principles. But what does this look like in practice?

First, it means going beyond traditional safety approaches. Human factors isn’t just about procedures or training – it’s about understanding how people perform tasks in reality. This includes:

- How operators interact with equipment during normal operations and maintenance

- What factors influence human performance (like lighting, access, time pressure)

- How teams communicate and coordinate during critical tasks

- What makes people take shortcuts or work around procedures

The strategy also requires sites to integrate human factors into hazard identification and accident investigation. This means:

- Looking beyond “human error” as a cause

- Understanding why actions made sense to people at the time

- Identifying the conditions that make errors more likely

- Finding opportunities to make tasks more resilient to human fallibility

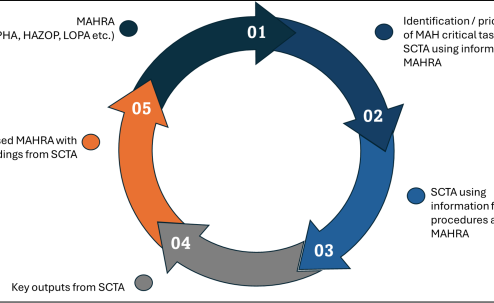

Critically, PABIAC expects sites to build competence in analysing safety critical tasks. By July 2025, all sites must identify their safety critical tasks and compile an action plan prioritising areas for improvement. This involves:

- Systematically identifying tasks that could lead to major accidents

- Breaking these tasks down to understand critical steps

- Assessing what could go wrong at each step

- Implementing effective controls that work in practice

Why Traditional Approaches Fall Short

Many paper and board facilities have robust safety management systems, detailed procedures, and comprehensive training programs. However, recent incidents show why these alone aren’t enough to meet PABIAC’s human factors objectives.

Over-reliance on Procedures

While procedures are essential, they often describe an idealised version of how work should be done rather than how it actually happens. This was tragically demonstrated when an operator was fatally injured after looking through a gap in machinery to check if tissue was being fed through correctly. The machine had been modified four months earlier to handle both single and two-ply paper, creating a dangerous trap point. While procedures existed, workers hadn’t received training on using the modified machine or on how to safely check paper feed.

After the fatality, the company installed clear plastic sheets over the gap so employees could check the machine without being at risk – a physical barrier higher up the hierarchy of risk controls, which is more effective than more procedures or training.

Equipment Design and Procurement

Traditional approaches often focus on engineering specifications without fully considering how people will interact with the equipment. In another incident, an employee sustained serious injuries to their lower left arm while attempting to re-feed paper following a break. When throwing the tail into the nip point, the paper wrapped around their arm, pulling them into the machine. The safety barrier in place proved inadequate to prevent access, resulting in amputation below the elbow.

These incidents highlight common issues:

- Controls that are difficult to access or operate

- Displays that are hard to read or interpret

- Maintenance points that are awkward to reach

- Systems that don’t match operator expectations

Reactive Rather Than Proactive

Many sites only consider human factors after an incident occurs. This reactive approach was evident when an operator was crushed to death inside a cardboard baling machine while attempting to clear a blockage. The employee, who hadn’t been formally trained, was working alone when paper jammed at the top of the conveyor. Because the machine hadn’t been isolated, its mechanism activated when they fell into the hopper, leading to the fatality.

This reactive approach means:

- Missing opportunities to prevent incidents before they happen

- Focusing on individual errors rather than system issues

- Implementing quick fixes rather than addressing root causes

- Not learning from near misses and everyday challenges

The Promise of Human Factors

The good news is that human factors offers solutions to these challenges. By understanding how people actually work and designing systems accordingly, organisations can achieve:

- Fewer incidents and near misses

- Improved operational efficiency

- Reduced downtime from unplanned maintenance

- Enhanced employee engagement and satisfaction

- Better regulatory compliance

Organisations that embrace human factors typically see benefits beyond safety, including operational efficiency gains, quality improvements, and greater workforce engagement. Rather than seeing people as the weak link, human factors leverages human adaptability as a strength while implementing systems that catch inevitable errors before they cause harm.

What’s Next?

In our next blog post, we’ll explore a systematic approach to human factors, aligned with regulatory expectations and the HSE’s Human Factors Roadmap. We’ll look at practical steps to identify critical tasks, analyse them effectively, and implement appropriate controls.

The complete guide is coming soon

We will be sharing our deeper dive soon.

This detailed resource will cover everything from identifying critical tasks to implementing effective controls, with real-world examples from the paper and board industry.

References:

PABIAC. PABIAC Strategy 2023 – 2027. Health and Safety – it’s in our hands: https://thecpi.org.uk/library/PDF/Public/health-safety/PABIAC/Strategies/23-27/CP021%20Pabiac%20Strategy%20Brochure_Final.pdf

HSE Human Factors Delivery Guide for COMAH sites: https://www.hse.gov.uk/comah/assets/docs/hf-delivery-guide.pdf

HSE. Making Paper Safely: Managing safety I the papermaking process. (HSG279). https://www.hse.gov.uk/pubns/priced/hsg279.pdf